WHY CHOOSING US ?

Persist in providing excellent products and after-sales service to the steel pipe industry customers globally.

Carry out chemical composition inspection for each piece of the raw pipes.

Nondestructive detection is executed for every single finished pipe.

Hydro-testing is inspected piece by piece according to the standards.

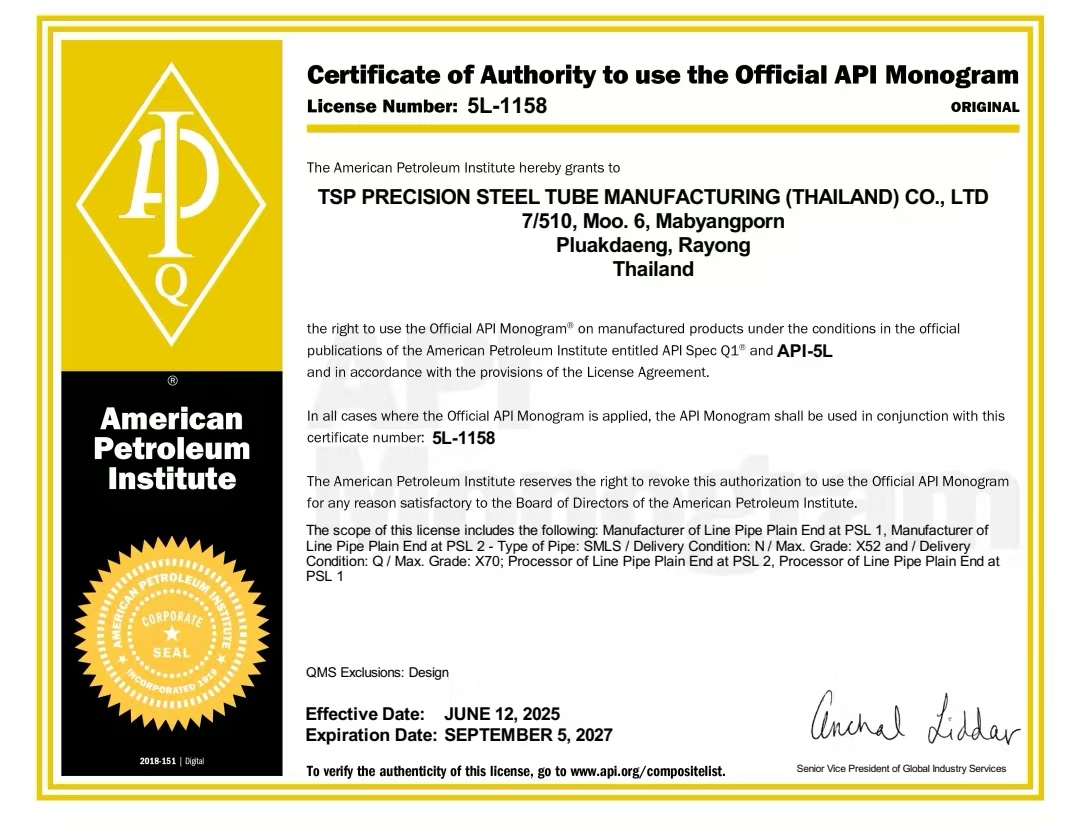

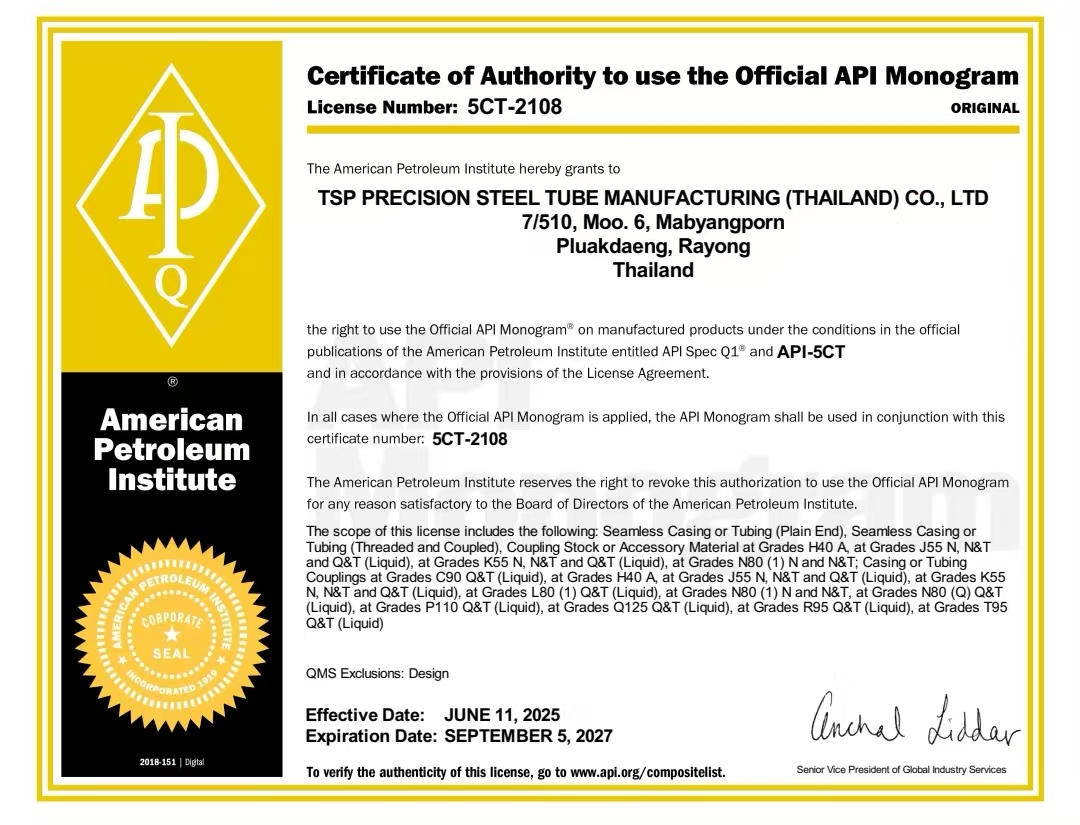

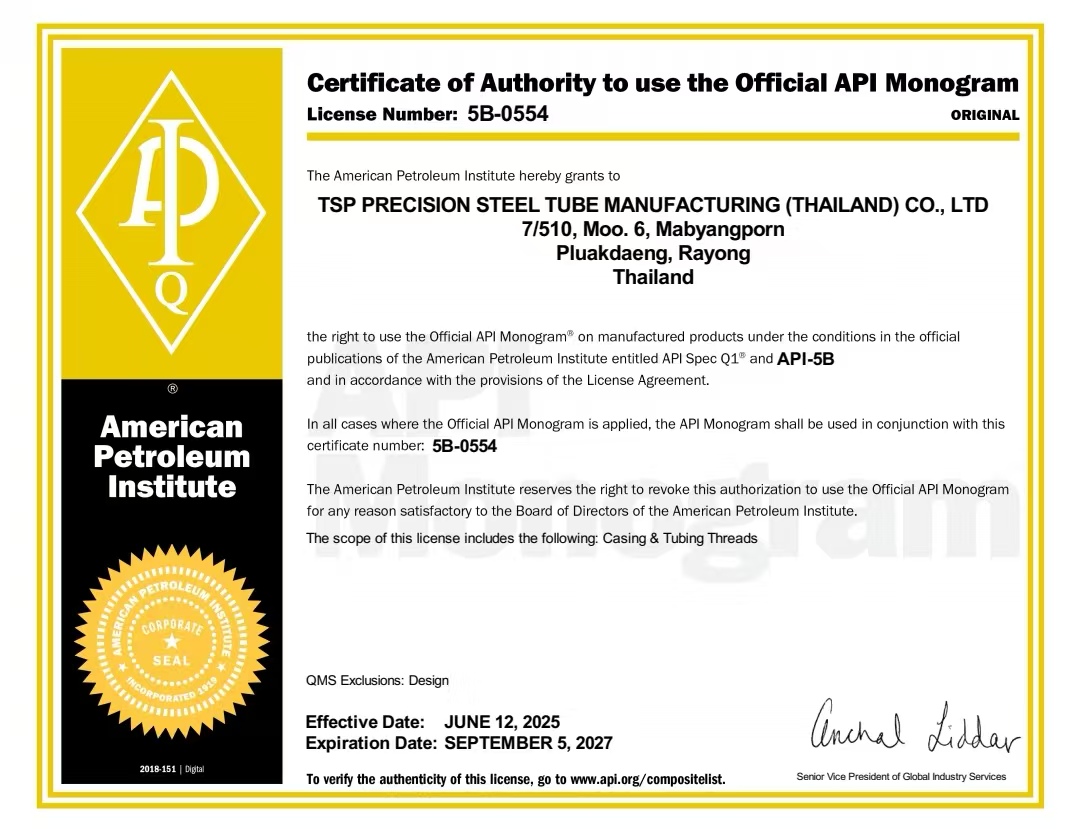

QUALITY ASSURANCE

Manufacturing Quality Assurance

Sourcing for Qualified supplier of raw materialMaking Quality Control PlanConfirming the Purchaser's Technical Requirements for the Raw MaterialInspection for Raw MaterialControl&Inspection of Products Throughout the Manufacturing ProcessInspection&Test for Finished PipesInspection&ConfirmationSales Quality Assurance

Major Facilities

Drawbench

Drawbench Hot finished

Hot finished Heat-treatment furnace

Heat-treatment furnace Point Straightener

Point Straightener Flaw Detection

Flaw Detection Hydro-tester

Hydro-tester Length measuring, weighing and marking

Length measuring, weighing and marking Packing

Packing

Laboratory

Multi-function tensile testing machine

Multi-function tensile testing machine Charpy Pendulum Impact tester

Charpy Pendulum Impact tester Spectrograph

Spectrograph Metalloscope

Metalloscope